The Supply Chain's Importance: A Comprehensive Guide To Its Essential Role

The supply chain is an intricate network of processes, spanning from raw material acquisition to the final delivery of products to customers. Its efficient management is pivotal for businesses, as it directly impacts their profitability and competitive edge. This guide aims to elucidate the critical functions of the supply chain, exploring its intricacies and offering strategies for optimization.

Understanding the Supply Chain

The supply chain is a complex ecosystem encompassing a wide array of activities and processes. It involves the movement and management of goods, services, and information from the inception of a product or service to its final delivery to the end-user. This chain of activities is designed to meet customer demands effectively and efficiently.

At its core, the supply chain is a strategic tool that can significantly impact a company's performance and market position. It is not merely a series of transactions but a carefully orchestrated system that connects various business functions and stakeholders. Effective supply chain management ensures that products are available when and where they are needed, at the right price and quality.

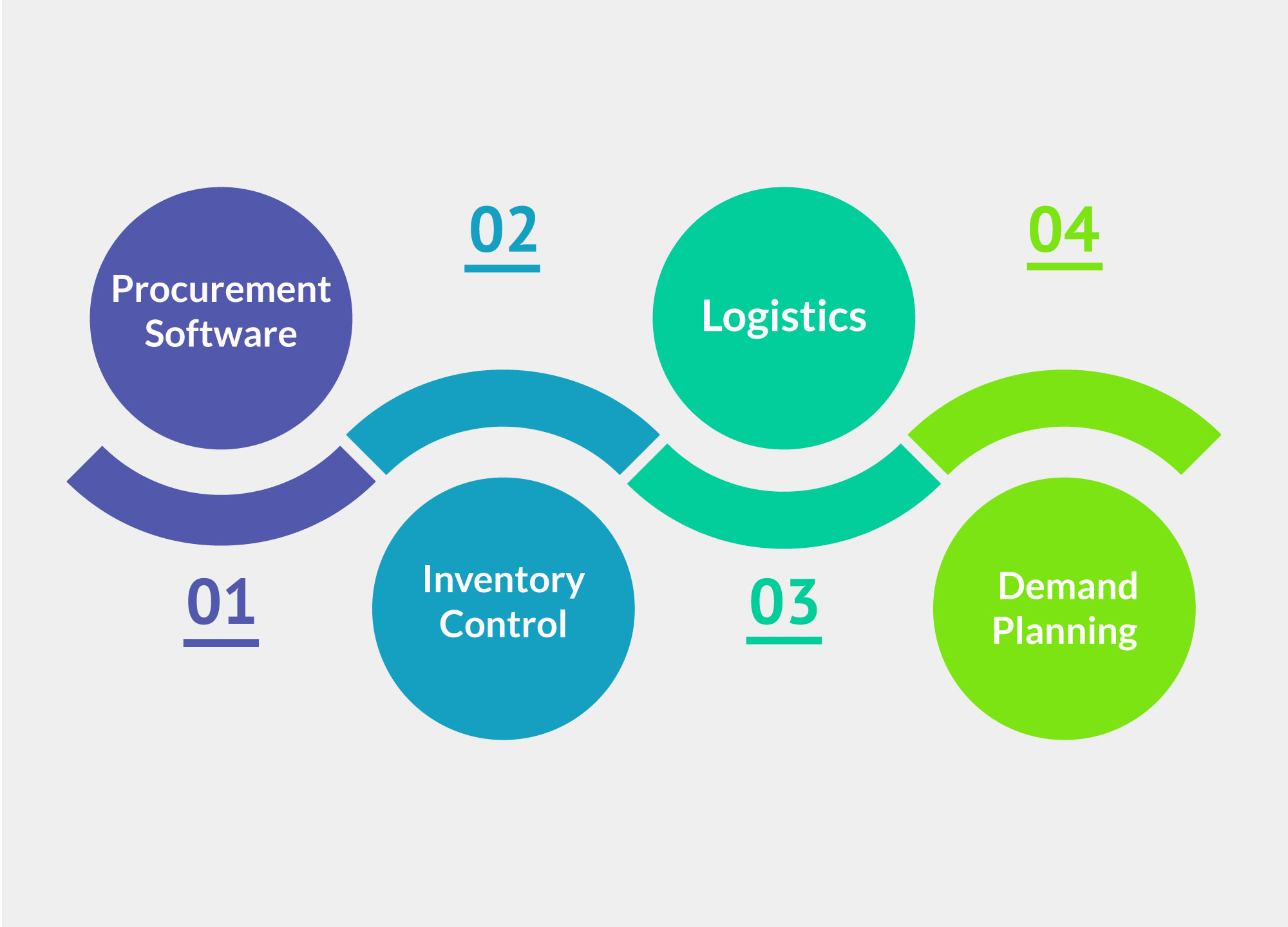

Key Components of the Supply Chain

The supply chain is composed of several interconnected components, each playing a crucial role in the overall process. These include:

- Procurement: This involves the acquisition of raw materials, components, and services necessary for production. It is a critical step as it directly influences the cost and availability of resources.

- Manufacturing: Manufacturing transforms raw materials into finished goods through a series of processes. This stage requires efficient resource allocation and management to ensure timely production.

- Logistics: Logistics encompasses the planning, implementation, and control of the efficient, effective flow of goods, services, and related information from the point of origin to the point of consumption. It includes transportation, warehousing, and inventory management.

- Distribution: Distribution involves the movement of finished goods from the manufacturer to the end-user. It includes sales and marketing activities, as well as the management of distribution channels.

- Customer Service: This component focuses on meeting customer needs and ensuring satisfaction. It includes after-sales support, warranty management, and customer feedback mechanisms.

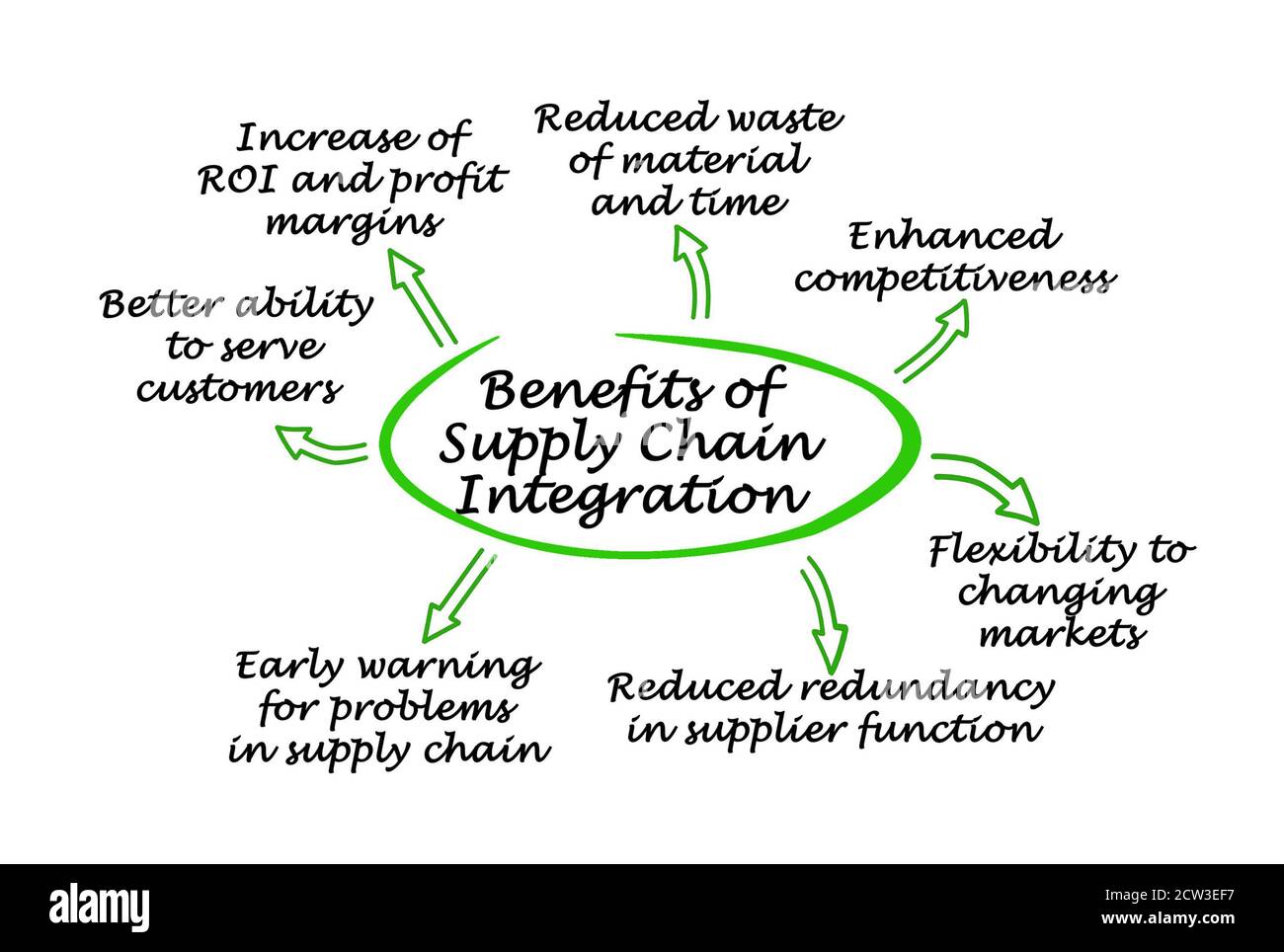

Each of these components is interconnected, and their effective integration is crucial for a smooth and efficient supply chain. Any disruption or inefficiency in one area can have a ripple effect on the entire system, impacting costs, delivery times, and customer satisfaction.

The Role of Technology in Supply Chain Management

Technology has revolutionized supply chain management, offering tools and systems that enhance efficiency, visibility, and control. Advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) have transformed the way supply chains are managed and optimized.

- AI and ML: These technologies enable predictive analytics, allowing businesses to forecast demand, optimize inventory levels, and streamline production processes. AI-powered systems can also automate various supply chain tasks, reducing human error and improving overall efficiency.

- IoT: The Internet of Things connects physical devices, vehicles, and other items to the internet, enabling real-time data exchange. In the supply chain, IoT devices can provide valuable insights into inventory levels, equipment performance, and transportation routes, leading to more informed decision-making.

- Blockchain: Blockchain technology offers a secure and transparent way to track and manage supply chain transactions. It can enhance traceability, reduce fraud, and improve supply chain visibility, especially in complex global supply chains.

Implementing these technologies requires careful planning and investment, but the potential benefits are significant. They can help businesses reduce costs, improve customer satisfaction, and gain a competitive edge in the market.

Supply Chain Optimization Strategies

Optimizing the supply chain is a continuous process that requires a strategic approach. Here are some key strategies to enhance supply chain efficiency and performance:

- Demand Forecasting: Accurate demand forecasting is crucial for effective inventory management and production planning. By analyzing historical data, market trends, and customer behavior, businesses can better predict demand and optimize their supply chain accordingly.

- Supplier Relationship Management: Building strong relationships with suppliers is essential for a stable and reliable supply chain. Regular communication, performance evaluation, and collaborative problem-solving can help ensure a consistent flow of high-quality materials and services.

- Inventory Management: Efficient inventory management is key to reducing costs and improving cash flow. Businesses should aim to strike a balance between having enough inventory to meet demand and avoiding excess stock that ties up capital.

- Transportation and Logistics Optimization: Optimizing transportation routes and logistics processes can significantly reduce costs and improve delivery times. This may involve leveraging technology for route optimization, utilizing multiple transportation modes, and implementing just-in-time delivery strategies.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): CPFR is a collaborative process that involves suppliers, manufacturers, and retailers working together to improve supply chain efficiency. By sharing data and insights, they can better align their plans and optimize the entire supply chain.

Implementing these strategies requires a holistic understanding of the supply chain and a commitment to continuous improvement. By focusing on these areas, businesses can enhance their supply chain performance, reduce costs, and improve customer satisfaction.

The Impact of Supply Chain Disruptions

Supply chain disruptions can have significant consequences for businesses, affecting their operations, finances, and reputation. These disruptions can arise from various factors, including natural disasters, political instability, economic fluctuations, and even cyber attacks.

To mitigate the impact of disruptions, businesses should have robust contingency plans in place. This may involve diversifying supply sources, implementing backup systems, and regularly reviewing and updating risk management strategies. By being prepared for potential disruptions, businesses can minimize their impact and ensure business continuity.

The Future of Supply Chain Management

The supply chain industry is evolving rapidly, driven by technological advancements and changing market dynamics. As businesses become more global and interconnected, the supply chain will need to adapt to meet new challenges and opportunities.

One key trend is the increasing focus on sustainability and environmental responsibility. As consumers become more conscious of the environmental impact of their purchases, businesses are under pressure to adopt sustainable practices throughout their supply chains. This includes reducing carbon emissions, minimizing waste, and promoting ethical sourcing.

Another trend is the rise of e-commerce and the increasing demand for fast, convenient delivery. To meet this demand, supply chains will need to become more agile and flexible, with a focus on last-mile delivery and efficient order fulfillment.

Additionally, the growing importance of data analytics and artificial intelligence will continue to shape the supply chain industry. Businesses will leverage these technologies to gain deeper insights into their supply chains, optimize processes, and make more informed decisions.

Conclusion

The supply chain is a critical component of any business, playing a pivotal role in its success and competitiveness. By understanding its complexities and implementing effective management strategies, businesses can enhance their supply chain performance, reduce costs, and improve customer satisfaction. As the industry continues to evolve, staying ahead of the curve and adapting to new trends and technologies will be essential for supply chain success.

What are the key benefits of effective supply chain management?

+

Effective supply chain management can lead to reduced costs, improved customer satisfaction, increased efficiency, and a stronger competitive position in the market.

How can technology improve supply chain performance?

+

Technology, such as AI, ML, and IoT, can enhance supply chain performance by enabling predictive analytics, automating tasks, and providing real-time data for informed decision-making.

What are some common challenges in supply chain management?

+

Common challenges include demand forecasting accuracy, supplier relationship management, inventory management, transportation optimization, and managing supply chain disruptions.

How can businesses prepare for supply chain disruptions?

+

Businesses can prepare for disruptions by implementing contingency plans, diversifying supply sources, and regularly reviewing risk management strategies.

What are some emerging trends in supply chain management?

+

Emerging trends include a focus on sustainability and environmental responsibility, the rise of e-commerce and last-mile delivery, and the increasing importance of data analytics and artificial intelligence.